Sewers • Drains • Pools • Water • Gas

Northwest Ohio's Top Choice for All Trenchless Solutions

Better Than New

Our technology allows us to restore aged, corroded piping systems in-place to a “better than new” condition without the use of chemicals or mechanical devices. The epoxy coating applied to the pipes’ interior, seal and protects the system from further deterioration and dramatically extends system life. The process can be used on a variety of pipe material including galvanized steel, cast/black iron, copper and lead.

How it Works

Our trenchless pipe repair process uses heated conditioned air to move a non-toxic abrading agent through designated pipe runs and segments. The movement of the agent through the pipe dislodges the corrosion buildup and transports it to an exit opening in the pipe where it is collected in a cyclonic grit unit and secondary dust collection system. The waste corrosion product is non-toxic and easily disposed of without any harm to the environment.

Pipe Layers Before

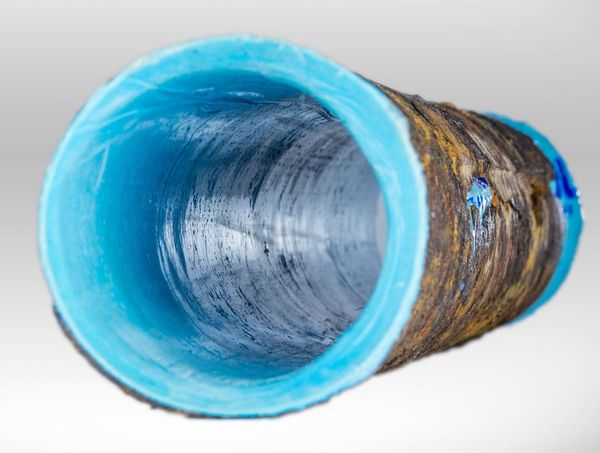

Pipe Layers After

The Result

The result is a clean, rust-free polished surface inside the pipe. Following pipe cleaning, a potable water safe, NSF61- certified* liquid epoxy is distributed through the piping using heated controlled air flow to facilitate optimal adhesion and curing. The coating will cure within 12-24 hours, after which time the system is re-assembled and returned to service next day. The result is a smooth and durable finish resistant to further corrosion and deterioration.

The Process

1. Identify the Problem by Sewer Camera

When we come to your home we will run a camera through your sewer main lines and/or kitchen/laundry lateral lines. From here the technician will be able to evaluate your needs and recommend the best solution trenchless sewer repair for your specific problem.

2. Access The Sewer Line

Two small holes are dug at either end of the sewer run that will be replaced. Cable is inserted at one end and fed through. One end of the cable is attached to a pneumatic jack while the other end is attached to a cone shaped bursting head.

3. New Pipe Inserted In Place Of Old Pipe

The bursting head is attached to a new seamless, heat-fused HDPE pipe. As the bursting head is pulled through the old sewer line, it simultaneously breaks apart the old pipe (even cast iron) and pulls behind the new pipe.